Reaction

Pharmira offers best solution to the themes given by our

clients through studying possibility both batch and

flow technology including process safeness.

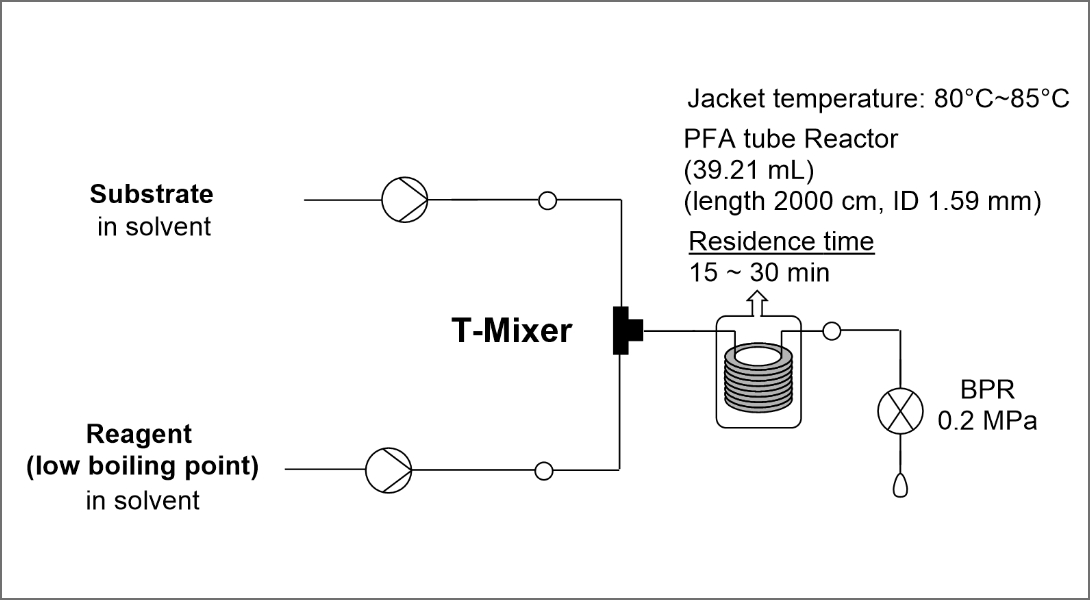

Example of flow reaction

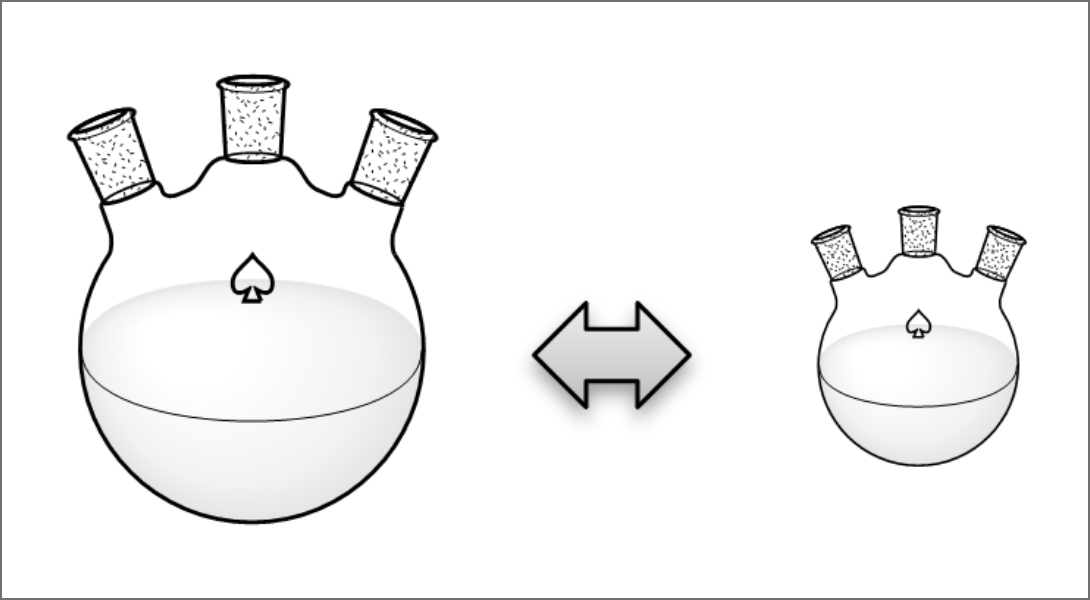

Gas-liquid reaction

Example to show the improvement of reaction rate by adopting flow reaction

Batch

In the condition of same injection scale, reaction rate depends on size of reactor (volume of gas layer, area between gas and liquid boundary ). In addition, scale up risk exists in scaling up from flask scale to tank scale.

Flow

Improvement of gas-liquid contacting efficiency

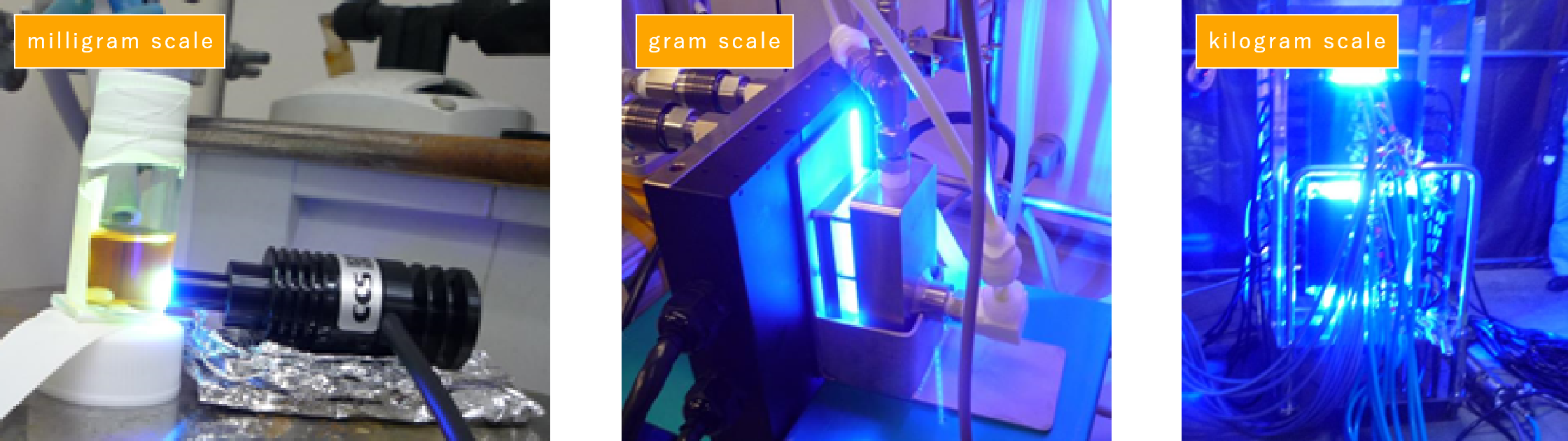

Photoreaction

Success for 60 times speed-up from initial laboratory scale condition by considering & designing conditions such as illuminant, solvent, photocatalyst.

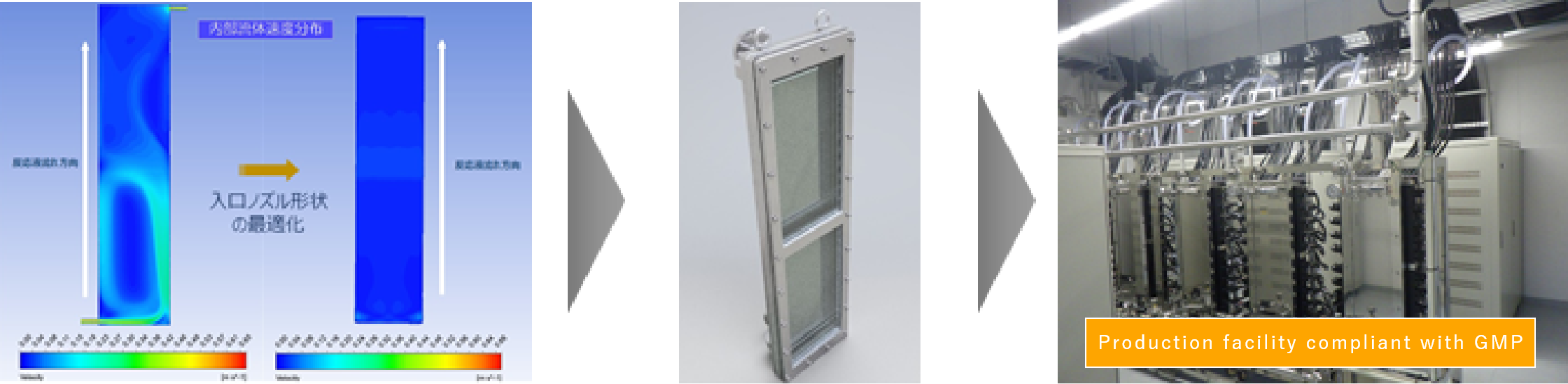

- ➡Facility design without ineffectiveness of light (by utilizing simulation technology)

・Uniformed flow in the reactor

・No remained gas bubble in the reactor produced by reaction

Commercialization is realized in Tokushima Plant of Shionogi Pharma.

Commercialization is realized in Tokushima Plant of Shionogi Pharma compliant with GMP

Road to scale up

Achieving scale-up by figuring out parameter of light illumination and utilizing simulation technology